You are here

News

JCB is set to showcase its super-efficient hydrogen combustion technology on the international stage for the first time ever with a debut in North America.

The wraps will come off JCB’s brand new hydrogen combustion engine - the company’s zero-carbon emissions solution for construction and agricultural equipment - at the Conexpo 2023 show in Las Vegas as part of the International Fluid Power Exposition (IFPE).

The JCB engineering team has made enormous strides in a short space of time to develop a hydrogen internal combustion engine and it already powers a JCB prototype backhoe loader and a Loadall telescopic handler. As the first construction equipment company to develop a fully working combustion engine fuelled by hydrogen, I’m delighted we are now able to present this technology on the international stage.

Lord Bamford | JCB Chairman is leading the project to develop JCB's hydrogen technology.

Leading the way in environmental, social and governance (ESG) for the construction equipment sector, JCB has been responsible for a series of industry innovations on its ‘Road to Zero’.

JCB developed the world’s first battery-electric mini excavator and has been at the forefront of electric technology development to meet customers’ demands for zero-carbon products with its E-TECH range. Today JCB has the largest electric line-up available in the construction industry and the company’s expertise in this sector will also be on show at the exhibition.

JCB’s commitment to reducing emissions goes back almost 25 years and its latest diesel engines have already delivered a 97% reduction in NOx emissions since 1999 and a 98% reduction in particulates. Today JCB’s diesel-powered machines also emit 50% less CO2 compared with those manufactured in 2010. JCB’s clean diesel engine technology will also be showcased on the stand in Las Vegas.

JCB machines from landmark years of Her Majesty the Queen’s 70-year reign took centre stage yesterday at the spectacular Platinum Jubilee Pageant in London.

The five diggers paraded down The Mall towards Buckingham Palace past members of the Royal Family and tens of thousands of cheering spectators who were lining the route.

Today the team of operators driving the JCB machines spoke of their pride and emotion at being involved in the tribute to The Queen as they drove machines manufactured in The Queen’s jubilee years of 1977, 2002, 2012 and 2022 – and one made in her coronation year 1953.

JCB Backhoe Loader Product Marketing Manager Julian Carder, 46, of Uttoxeter was driving a 1977 JCB backhoe from the year of the Queen’s Silver Jubilee – a machine he restored to its former glory in 2012.

It is hard to find the words to describe what an amazing occasion this was. The response the JCB machines received from the crowds, who were at least 10 deep along most of the route, was simply incredible. They were waving and cheering us as we drove the machines down The Mall, and it was a very emotional experience. We are all very proud to have taken part in such a fantastic tribute to The Queen.

Julian Carder | JCB Backhoe Loader Product Marketing Manager

JCB Test Site Operator Georgina Williams, 30, of Derby brought the parade of JCB backhoes right up to date as she drove a 2022 model powered by hydrogen. The machine is currently being developed by the Staffordshire-based company as it explores the potential of hydrogen as a zero CO₂ alternative to fossil fuels.

Georgina said: “The highlight for me came when we drove through Admiralty Arch and took in the scene in front of us – the flags in The Mall and the tens of thousands of people waving and cheering. It was simply amazing and a once in a lifetime experience.”

Leading the parade was one of the first backhoe loaders ever built by JCB in 1953 - the year of Her Majesty’s Coronation - driven by Andy McLeod, of ABM Plant Hire, of Derby. JCB demonstrator Dan Potter, of Rocester, was driving another iconic JCB 3CX backhoe from 2012 – the year of the Queen’s Diamond Jubilee.

At the end of the Pageant the team was ushered to the front of the gates of Buckingham Palace with everyone else who had taken part to witness the culmination of the event - a balcony appearance by Her Majesty the Queen and members of the Royal Family.

JCB Demonstrator and father-of-two Matt Lucas, aged 50, of Werrington, Stoke-on-Trent, drove a 2002 JCB backhoe loader made in the year the Queen celebrated her Golden Jubilee. He said: “The moment when the Queen came out on the balcony was very emotional. The roar of the crowd and the singing of the National Anthem in front of Buckingham Palace at that moment is something I will never forget.”

Yesterday’s Pageant was the culmination of celebrations to mark The Queen’s 70 years on the throne. It involved more than 10,000 people and told the story of the monarch’s seven-decade reign through music, dance and fashion.

Prime Minister Boris Johnson today officially opened JCB’s newest factory in India as the company strengthens is global manufacturing presence.

Prime Minister Boris Johnson today officially opened JCB’s newest factory in India as the company strengthens is global manufacturing presence.

With 11 factories in the UK employing more than 7,500 people, JCB first began manufacturing in India in 1979 and is now the country’s leading producer of construction equipment.

Today Mr Johnson visited JCB’s latest factory in India – a £100 million investment plant in Gujarat which will fabricate parts for global production lines. The new factory is located in Vadodara near the port city of Surat on the West Coast of India.

Joining the Prime Minister today at the opening was JCB Chairman Lord Bamford, who led JCB’s expansion in India in the late 1970s, including the opening of its first factory in Ballabgarh, near Delhi. Today JCB has six factories in India at locations including Jaipur and Pune.

In its first year of full production, JCB India manufactured just 39 machines and by next year will have made a total of half a million. This country is now a major engineering power and being here has transformed our business. It has been a fabulous success, with so much more potential for growth. Such progress has only been possible by continued investment and the opening of our new Gujarat facility is an important step in growing our business here and around the world.

Lord Bamford | Chairman JCB

JCB India CEO and MD Deepak Shetty said: “This new facility will create around 1,200 direct jobs when complete and thousands more in the supply chain. It will also be a benchmark in the industry on gender diversity and modern technologies in laser cutting, welding and machining. Vadodara is a strategic location for JCB India given its proximity to ports and availability of raw materials and skilled talent. We would like to thank the Government of Gujarat for its phenomenal support with this project.”

India has been JCB’s biggest market every year since 2007 and one in two of every construction machine sold in India today is made by JCB. The new facility, which is on a 47-acre site, will be capable of processing 85,000 tonnes of steel annually.

The new plant will be a gender diverse manufacturing facility employing 50% women. JCB India has also set up a skills centre at the plant where young professionals will be trained to work on diverse job roles in manufacturing.

Digger giant JCB is leading the charge for a low emissions future by investing in a fleet of new hybrid electric company cars.

Hot on the heels of the launch of its all-electric mini excavator and Loadall telescopic handler and the unveiling of the construction industry’s first hydrogen-powered prototype excavator, JCB is building on its eco credentials with the purchase of 40 Toyota Corolla Touring Sports self-charging models.

The first 20 of the vehicles - manufactured 16 miles away from JCB’s World HQ at Rocester in Burnaston, Derbyshire - have been delivered ready for JCB’s sales and service teams to get behind the wheels. The new fleet is all white as it has been since the 1960s when company Founder Joseph Cyril Bamford read research suggesting white was the safest colour to have on the road.

"JCB is making great strides in developing low emissions technology to power its range of construction equipment and we are delighted to complement this strategy with the introduction of self-charging hybrid cars into our fleet. It’s also very pleasing to be able to support another global business which manufactures on the doorstep of JCB and one which makes such an important contribution to the regional economy."

Mark Turner | JCB Chief Operating Officer

Stuart Ferma, General Manager Toyota and Lexus Fleet, said: “It is extremely gratifying that, with JCB already working to address the future challenges within its industry with new technology, it has chosen Corolla hybrid models for its vehicle fleet. With our shared support for British manufacturing and our commitment to develop hydrogen as a fuel of the future, we share very similar goals.”

The British-built Corolla models are all powered by Toyota’s highly efficient 1.8-litre hybrid system and are in Icon Tech specification.

JCB has set a new British speed record for tractors with its high-speed Fastrac tractor.

The tractor notched up 103.6mph at Elvington Airfield, near York, with TV presenter and engineering guru Guy Martin behind the wheel. It smashed the previous 87.27mph record set in March 2018 by Top Gear’s Track-Tor.

Guy Martin said: “It had been a great day with the JCB at Elvington, proper job with some right proper engineers. She felt rock steady on the runway, job’s a peach.”

A team of JCB engineers has been working on the secret project to develop the tractor over the past few months and today JCB Chairman Lord Bamford praised their “amazing achievement.”

“We’ve long harboured a dream to attempt a speed record with the Fastrac and the whole team has worked tirelessly to achieve this amazing result. I’m extremely proud of what they have achieved in such a short space of time.”

Lord Bamford | JCB Chairman

The chairman went on to say. ‘‘It is British engineering at its best and it really does highlight the skills and innovation we have in our engineering team. They have done a truly fantastic job.’’

It was Lord Bamford’s idea to develop a tractor which had a high road speed capable of field work and the speed record achieved yesterday came exactly 28 years to the day since the first production model rolled off the line.

JCB is no stranger to land speed records. In 2006, its DieselMax streamliner set a new diesel land speed record when it reached 350.092mph on Bonneville Salt Flats in the USA, using two JCB DieselMax engines. It’s a record that still stands to this day.

Based on the Staffordshire maker’s Fastrac farm tractor, the record-breaking tractor is powered by JCB’s 7.2 litre, 6-cylinder DieselMax engine produced at its factory in Derbyshire. Capable of delivering 1,000hp and 2,500Nm of torque, the Fastrac had been put on a diet and had its aerodynamics enhanced with the help of Williams Advanced Engineering.

The full story of the Fastrac's record-breaking feat will be told in a special Channel 4 programme in the UK to be aired later in the year.

JCB has been granted a preliminary injunction by a French court against Manitou which orders the company to stop producing telehandlers featuring a patented JCB productivity device.

The ruling by the Judge at Court of the First Instance in Paris means that the company, based near Nantes, cannot manufacture, sell or lease telescopic handlers equipped with the patented feature.

JCB CEO Graeme Macdonald said: ‘‘We invest many millions of pounds in developing and patenting innovative and sophisticated engineering solutions which benefit our customers all over the world. We will not tolerate any copying or infringement of our intellectual property rights wherever in the world they occur.’’

“We invest many millions of pounds in developing and patenting innovative and sophisticated engineering solutions which benefit our customers all over the world.”

During operation of Loadall telescopic handlers fitted with JCB’s patented Longitudinal Load Moment Control (LLMC) system, sensors monitor the weight being retained on the rear axle. If the sensors detect the rear axle weight is reducing past a pre-set threshold, then the system gradually locks out the hydraulics to prevent further weight being transferred from the rear axle to the front, therefore avoiding the machine tipping forward.

To allow operators to drive continuously without any loss of productivity, JCB has a patented feature on its LLMC system that automatically disengages the device while the machine is moving (EP 2 263 965). This feature prevents JCB’s telehandlers unnecessarily locking out the hydraulics and giving false indications of instability when the machine is simply re-handling or travelling over rough ground. It is the use of this feature the French court has ordered Manitou to cease by March 13th. The court also ordered Manitou to pay costs in the case.

Construction work on the new £50 million JCB Cab Systems factory is forging ahead as it targets a summer opening.

The shell of the 350,000 sq ft plant next to JCB Heavy Products and the World Parts Centre at Uttoxeter is on course to be completed slightly ahead of schedule ready for high-tech production line facilities to be installed from March onwards.

The investment, one of the biggest in the company’s history, will create the most advanced and productive cab facility in the world with a computer controlled production line, fully-automated painting facility and robotic welding. The new site will accommodate 400 employees, who will relocate from Rugeley.

JCB Cab Systems’ General Manager David Carver said: “We are delighted with progress on the new site. A strong team focus on the delivery timeline and favourable weather means completion of the infrastructure and main building is ahead of schedule. Our focus is on building a plant that supports the company’s global growth plans and enables us to work far more efficiently.

“A weld automation facility destined for the new factory is currently being trialled at Rugeley. In addition, a computer-controlled production line, fully-automated painting process, and other high-tech features will ensure we have the most advanced cab facility in the world. A phased programme of moving production to the new site will be implemented from July onwards.”

JCB has developed its first ever electric digger in response to customer demands for a zero emissions machine which can work indoors, underground and close to people in urban areas.

The 1.9 tonne mini excavator can be charged by simply plugging it into a standard 230 volt domestic electricity supply. Once fully charged, it is ready to put in a full normal working day on the building site – digging with the same speed and power as its diesel counterpart. Super-fast charging will also be available at launch, slashing the charging time in half.

The innovative product goes on sale at the end of year after being developed in secret at the company’s Staffordshire HQ. Its development has been spearheaded by company Chairman Lord Bamford who today heralded its arrival as a “real breakthrough” for the construction sector.

Lord Bamford said: “JCB has been at the forefront of developing innovative, low emission diesel powered construction equipment for decades. In fact, thanks to our clean diesel technology, typical JCB machines will be pretty close to zero emissions by next year.

“However with urbanisation, machines are operating more closely to people as well as digging underground, indoors, near hospitals and in food production environments. As a result, there is a new zero emissions sector emerging and it’s emerging very quickly. It’s for this reason we have put ourselves at the forefront of alternative power technologies and developed the first ever electric JCB digger.”

The machine – known as the 19C-1 E-Tec - will not only deliver zero emissions, it will also be the quietest in the JCB range. This means contractors can work after normal hours in urban streets, around hospitals and close to schools without disturbing people. The machine also has a retractable undercarriage to enable it to negotiate tight spaces.

The electric excavator has an electric motor and three advanced lithium-ion battery packs, to deliver a full energy capacity of 15kWh.

TV celebrity Richard Hammond today got behind the controls of two of the world’s most innovative machines manufactured for the construction and agricultural industries.

The Grand Tour presenter visited JCB’s World Headquarters at Rocester, Staffordshire and JCB Heavy Products in Uttoxeter where he put the company’s high-powered machines through their paces.

He took the controls of the brand new 20-tonne tracked excavator, the 220X, which was launched earlier this year following a £110 million development programme. Next for a test drive was the high speed JCB Fastrac 8000 Series tractor, which reaches speeds of 70kph.

“It’s great to be here at JCB where the machines are so tough that I think even I will struggle to break anything. JCB is an iconic brand and when you think of engineering excellence, boldness and innovation, these big yellow machines are right up there with the best.”

JCB Worldwide Marketing Director Michael Plummer said: “Richard has driven many vehicles over the years and we are delighted that JCB’s machines have been put through their paces by such a well-respected authority in the motoring world.”

13 July 2017

A leading Mauritian building and civil engineering firm has placed its largest ever equipment and attachments order – with a deal for JCB equipment worth Rs60 million.

The massive investment has seen Best Construct order 16 new machines in total. Supplied by MECOM, the full line-up includes: 4x JCB 85Z-1 midi excavators, 4x JCB 86C-1 midi excavators, 4x JS140 tracked excavators and 4x JCB 3CX backhoes, the latter being delivered in July 2017. All the midi excavators will be equipped with compactors for the first time in Mauritius.

This milestone order takes Best Construct’s JCB fleet to a total of 33 machines, with 70 machines in total working across a dozen of Mauritian sites at any one time. The latest arrivals will be put to work across the Island on a one billion rupees water pipework rehabilitation programme aiming at giving 24hr access to drinking water for the whole Island population.

The Best Construct executive team visited various JCB factories in the UK in July accompanied by Jean-Luc Mamet, MECOM’s Sales Manager for JCB and JCB’s Business Development Manager for Africa, Andrew Boyers.

Best Construct’s Executive Director, Dayen Murden said: “The newly delivered 3CX are performing well as usual, returning good fuel economy and proving popular with our operators for their smooth operation and all-round capabilities. We decided to order the new compact excavators as we are going to operate on various sites with space constraints and within residential areas where noise pollution is going to be an issue. The new models are very silent and the decision to buy exclusively JCB gives us consistent control systems across the fleet – so operators can easily switch between machines and on top of that the LiveLink system is proving to be a very productive monitoring system”.

“We have always found JCB products to be reliable and well-priced, with strong residual values and we receive great support through our long-standing relationship with our local dealer MECOM.”

Best Construct was founded in 2002 by Dayen Murden and now employs 400 people. Its core services include: Drain works, infrastructure works for social housing projects, road construction and construction of residential plots.

JCB has won one of the biggest engine supply deals in its history after securing an annual contract worth around £4.5 million.

The milestone agreement will see the company supply Terex GB Ltd with engines to power site dumpers made at the firm’s Coventry plant – just as JCB celebrates a landmark 10 years of engine manufacturing.

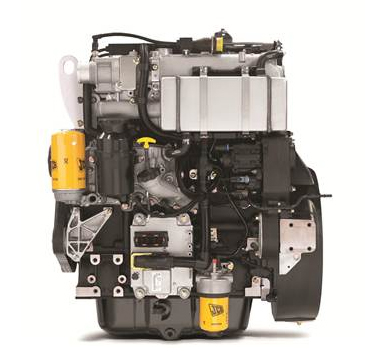

The engines - made by JCB Power Systems in Derbyshire, UK - will be the latest fuel efficient Ecomax 55kW/74HP stage3B/Tier 4 Final models. Initially they will power two Terex site dumpers in its range: the TA6 and TA6S.

JCB CEO Graeme Macdonald said: “The engine supply contract is a major milestone for the JCB Power Systems business. It is one of the biggest engine supply deals in the company’s history and is testament to reliability and efficiency advantages that the JCB Ecomax engine offers customers.”

JCB began producing engines at its plant in Foston, Derbyshire at the end of 2004 and engine production was extended to India in 2011. To date JCB has produced 350,000 engines globally. JCB engines now power more than 70 per cent of JCB’s products. JCB Power Systems is also enjoying growing success in selling engines to other industries worldwide.

In Mauritius, the JCB engines now power the JCB backhoe loaders, excavators, telescopic handlers, wheeled loaders and generators.